Architectural Plywood

Architectural Plywood

Quick Lead Time – With No Added Freight!

VENEER INFO

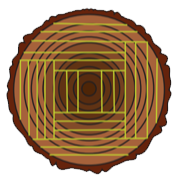

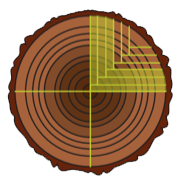

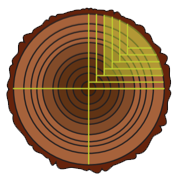

MATCHING VENEER LEAVES WITH A PANEL

More Information

-

Panel Sizes

Panel sizes are 1/8″ – 2″, 4′ x 8′ up to 5′ x 12′

Long Grain and Cross Grain Counter Front Material (Correct Sanding with The Grain)

-

Core Options

The core options are MDF, Veneer Core, Particle Board, Fire Rated, Moisture Resistant, Formaldehyde Free and Marine & Exterior.

-

Available As

Running Book Matched, Balance Book Matched, Running Slip Matched, Center Balance Matched, Flitch Matched, Random Matched, End Matched, Sequenced & Numbered.

-

Edge Banding

7/8 & 13/16 Pre-Glued, 15/16 & 7/8 Non-Glued Automatic

-

Veneers

2-Ply Wood Backer, 10-mil, 20-mil , 30-mil Paperback, Phenolic Backer, Peel & Stick Adhesive Backer

Thick Face/Rough Sawn/Scratched Veneer & Recon Veneer

-

Special Machining

Cut to Size, Custom Finishing, UV Finished, UV Seal/Fill, Colors & Stains and Water Based Primer

-

Features

- Numerous premium domestic, exotic, crotch, and burl veneers

- Architectural Plywood with your choice of veneer face, back & core

- Specialty cores available in various sizes (Fire Rated/Nauf/etc.)

- Ask about our FSC®-Certified Cores and Veneers

- Specializing in Cut to Size and Blue Print Matching

- Edge Banding

- Sketch Face Panels – Diamond, Reverse Diamond, Box, Starburst

- Matching & Many More

- Flexible Veneer Backers available – 10, 20, 30 Mil. paper, Polyback and 2-Ply (wood backer)

- Aggressive lead times and delivery on Most Products.

-

Items To Consider When Ordering Plywood

- Number Of Panels

- Core Type & Thickness

- Width & Length

- Species & Grade Of Front/Back

- Matching Requirements

- Application & Intended Use

Brands you can trust

We carry only the highest quality wood products by the best brands in the industry. We carefully select the brands we distribute; they must be of the highest quality and employ the very latest in industry standards. We take our product selection very seriously because we want only the best for our clients. Your satisfaction is our top concern.