Garnica Ultralight XPS Foam Core

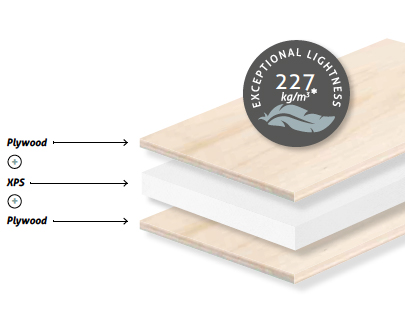

As a global reference in the production of plywood panels, Garnica has developed an innovative range of ultralight products. Combining the excellent mechanical properties of Garnica plywood –lightness, stability and machinability– with an insulating and ultralight material such as extruded polystyrene produces a panel with improved performance.

Ultralight sandwich panels comprise an insulating XPS core, plywood panel made from European poplar sourced from sustainable plantations and a wide range of finishes of exceptional surface quality. The Ultralight product range is the lightest plywood that Garnica currently produces and is an excellent solution for numerous applications.

Exceptional Properties

Exceptional Properties Its extremely lightweight nature in combination with a robust structure gives Ultralight a series of characteristics that perform better when compared with conventional panels:

- The 18 mm panels are 45% lighter while the 60 mm panels can be up to 75% lighter than standard poplar plywood

- This lightweight nature is maintained even in giant format pieces

- Easy to handle, both during transport and production

- Easy to machine using all sorts of tools: traditional, CNC and wood shapers

- 30% faster cutting

- Perfect for covering with any type of material: veneers and papers, HPL/CPL, aluminium, HDF/MDF, etc.

- High-quality XPS core: exceptional thermal insulation, high mechanical resistances, low weight, high water tolerance, uniform seal and cellular structure

RESOURCES

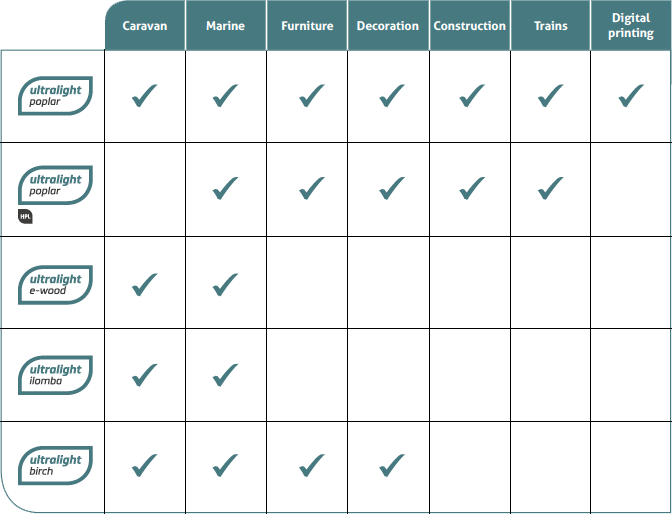

PRODUCTS

ultralight poplar

Light-coloured poplar faces of exceptional surface quality that are ideal for painting, filming/laminating or digital printing.

ultralight birch

Decorative birch faces with soft and warm tones and elegant grain that are perfect for decoration and furniture.

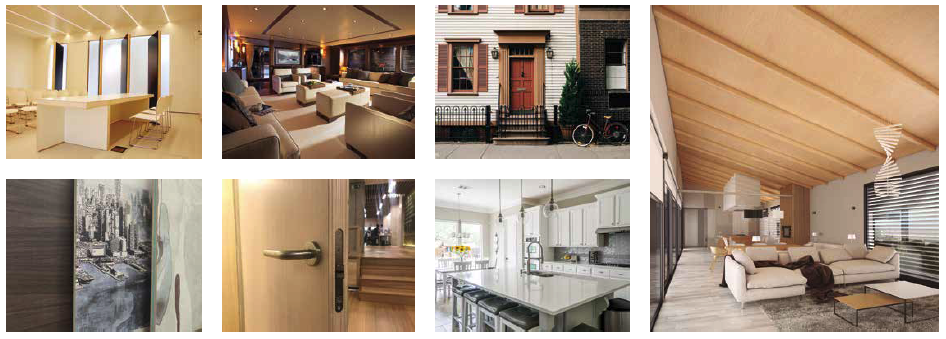

Applications

Ultralight is specifically designed for applications seeking to lighten weight load, such as the caravan industry and the furniture and decoration trade, or where thermal insulation is especially important, such as doors, roofs or panelling.

Ultralight is perfect in each one of these industries or sectors for use in countless specific applications:

- Interior construction and furniture for caravans, boats and all type of vehicle

- Decoration and furniture for any interior design project

- Ceilings and panelling for buildings

- Stages and decorations

- Doors, floors, wall interiors and any kind of construction component

- Building models

- Trade fair stands and window displays

- Digital printing for posters, signs and any advertising medium

- Perfect for laminating or painting because of the high quality of the poplar faces

Recycling

Ultralight has a very long life cycle, meaning there are numerous ways to reuse the product. The best way to manage Ultralight sandwich panels is to reuse them in another application. Recycling methods vary from one country to another owing to specific legislation in each case. Always follow the rules that apply locally. Specialised companies shred sandwich panels and recycle each part separately. Panels can also be repurposed at energy recovery plants.

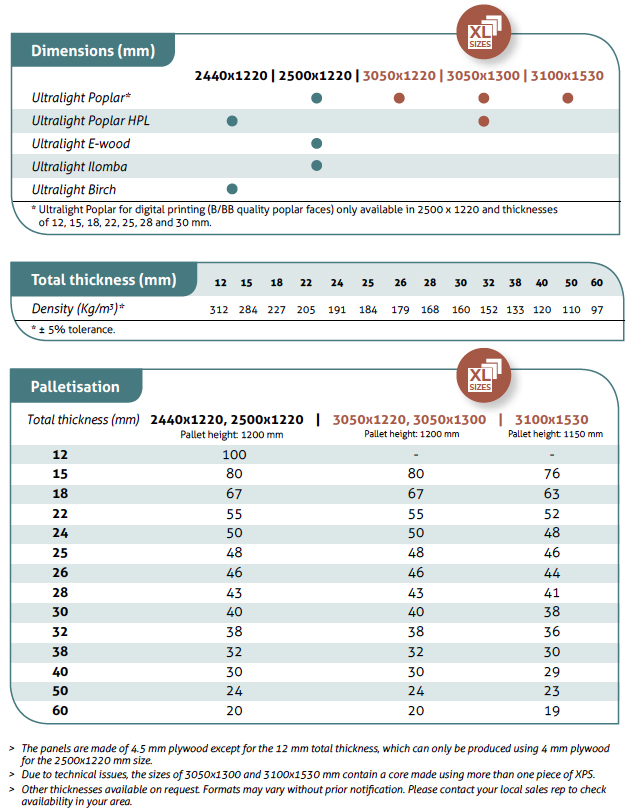

Formats

The composition of Ultralight has been optimised and comes in a wide range of sizes and thicknesses so it can be adapted to numerous projects.

Protection against Fire

The extruded polystyrene (XPS) used for the Ultralight core as insulation is an HBCD-free flame retardant component and contains none of the foam blowing agents CFC and HCFC. According to Specification STM-S-001, Index D (2014), Ultralight possesses a very low smoke gas index and has been classified as F1, a material of low toxicity. The I.F. smoke gases index measures the maximum specific optical density (Dm), the smoke obscuration value (VOF4) and the toxicity index (I.T.C.). The test establishes requirements related to the smoke and potential toxicity of practically all flammable materials on a railway vehicle.

Acoustic Insulation

The XPS core and excellent physical-mechanical properties of plywood panels from Garnica mean that Ultralight possesses outstanding levels of thermal and acoustic insulation. Ultralight has been accredited by the most demanding acoustic tests, such as the UNE-EN ISO 10140-2:2011 standards. It has been laboratory tested to measure acoustic insulation and accredit its use in construction. Please contact your local sales rep to see the tests.

By providing greater mechanical inertia to the assembly owing to perfect industrial adhesion capacity, this combination of layers in the form of a sandwich panel also creates a stiffness in the Ultralight panels that is genuinely surprising when considering their lightweight nature and easy machinability. Determination of screw pull-out resistance from fibreboards is performed under UNE EN 320:1993 standards.

Technical Product Manual

For more information about panel connections, technical analysis, pre-dimensioning tables, structural thickness, density, technical characteristics with other materials. creating panel connections and best practices for use click the button below.

BRANDS YOU CAN TRUST

We carry only the highest quality wood products by the best brands in the industry. We carefully select the brands we distribute; they must be of the highest quality and employ the very latest in industry standards. We take our product selection very seriously because we want only the best for our clients. Your satisfaction is our top concern.

Chesapeake Plywood 3400 East Biddle Street. Baltimore MD, 21213

Tel: 410-244-0055 – Fax: 410-244-1269