Iberian Fumed Eucalyptus

Iberian Fumed Eucalyptus is common in the Iberian region, eucalyptus is a very rewarding wood species in contemporary interior design. The wood has a very nice structure with clearly distinguishable growth rings. The smoking process gives the veneer an intense dark color with variations from light golden brown to intense dark brown.

Fuming wood is a technique which has already been in use for a long time to lessen color differences and obtain a honey-brown to deep black color. For this Iberian Fumed Eucalyptus, our artisans use old world techniques adapted for modern technology. Under their watchful eyes the wood is smoked in modified kiln dryers in a precision environment.

Features:

- Finest natural eucalyptus

- Typical wood grain

- Carefully sourced from well managed sources

- Golden brown to intense dark brown color due to the smoking process

- Versatile and easy to work with

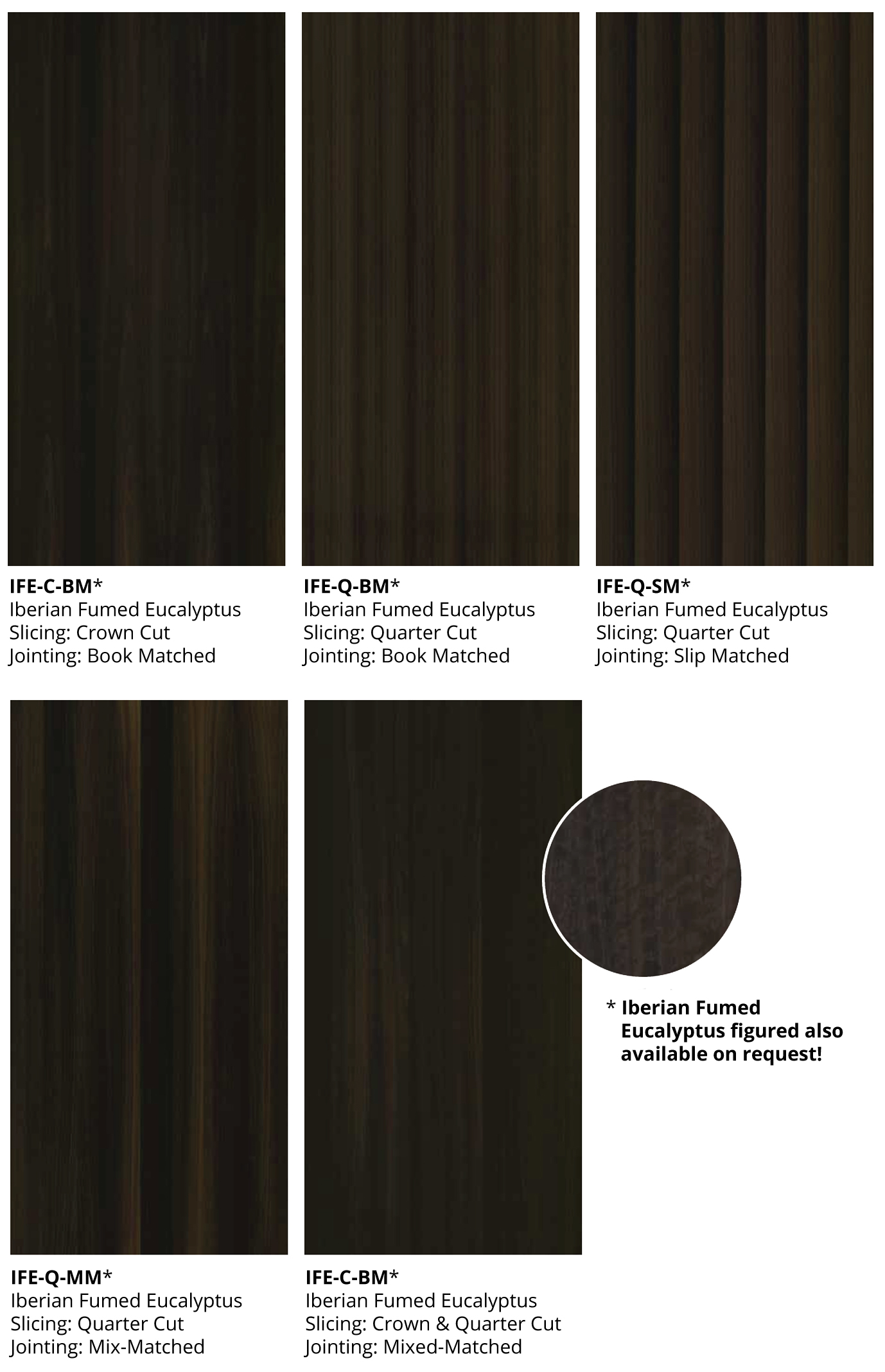

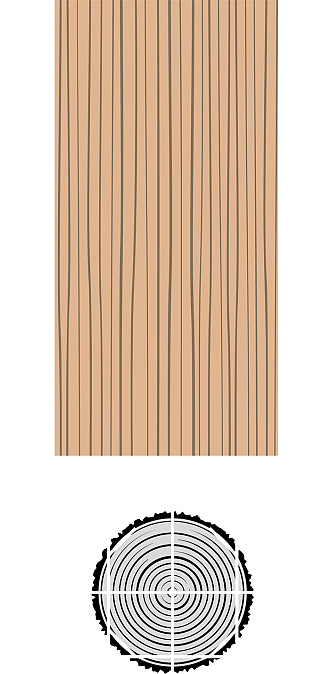

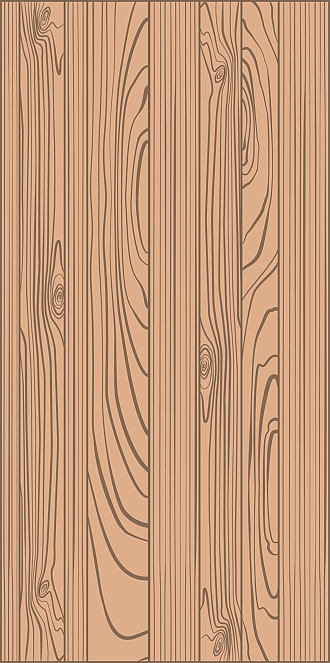

Slicing Techniques

Crown Cut / Plain Sliced

Quarter

Quarter + Crown Cut

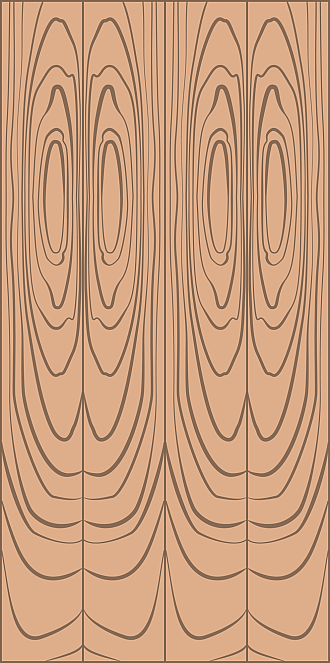

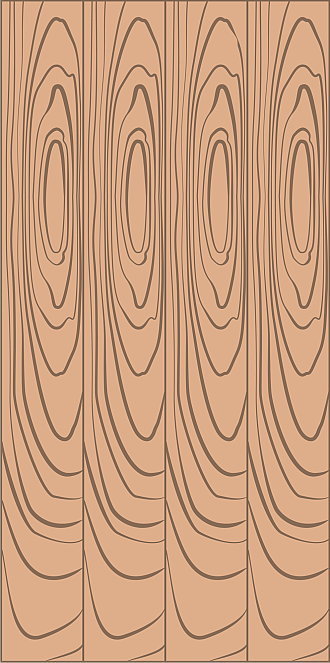

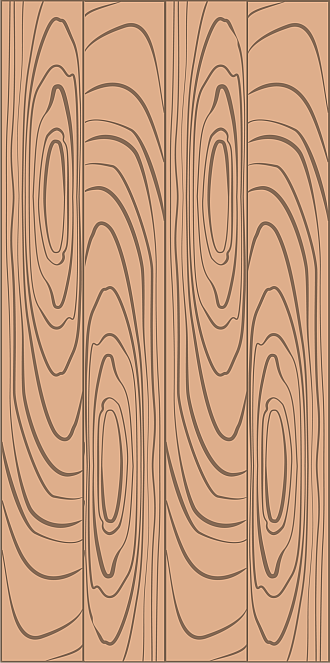

Jointing Techniques

Bookmatch

Slipmatch

Reverse Slipmatch

Mixmatch

Careful selection

Our Iberian Fumed Eucalyptus veneer curators vast experience and expertise in wood sourcing gives us a distinct advantage unparalleled in our industry. Our network consists of reliable and skilled partners, procuring wood according to a strict quality manual to which only a few key persons have access. Venturing through many forests, our curators select the most exceptional logs to yield veneers suitable for Decospan’s Bespoke Collection. Sustainability is just as deeply rooted in our selection process as is quality. Hence Decospan’s Pure Wood Charter that all partners are required to sign and comply with. Decospan has been certified under both FSC and PEFC programs for many years and strives to promote sustainable forestry.

“The sustainable use of our basic raw material – wood veneer – gets the highest priority and is embedded in our company philosophy.”

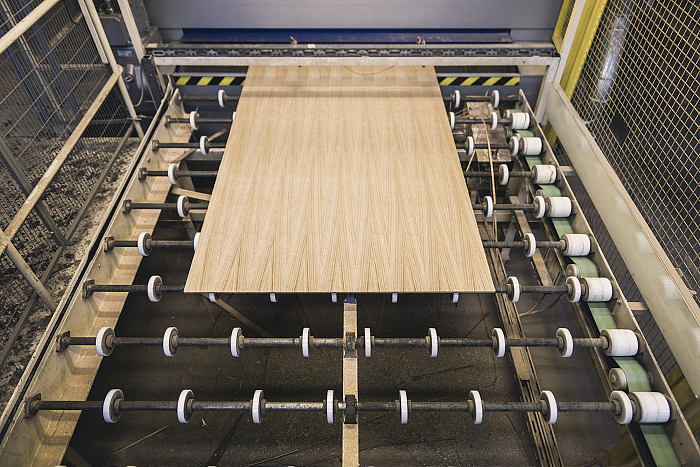

Controlled slicing

Iberian Fumed Eucalyptus veneer is produced by slicing a log in thin layers with a blade. In contrast to solid wood, which is sawn, veneer makes optimal use of the log without any sawing loss. This is how we make sure that this precious raw material is used as optimal as possible. We have partnerships with veneer factories that go back many years and where the exchange of experience and knowledge have led to unique veneer products.

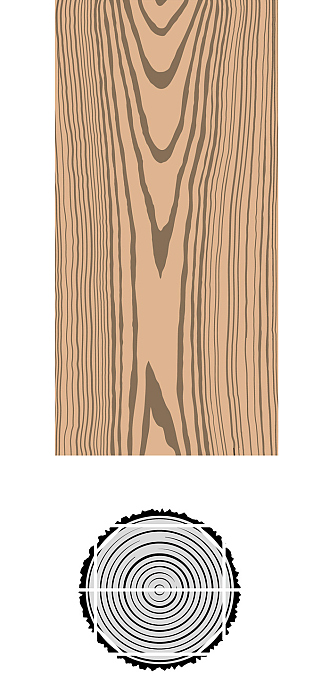

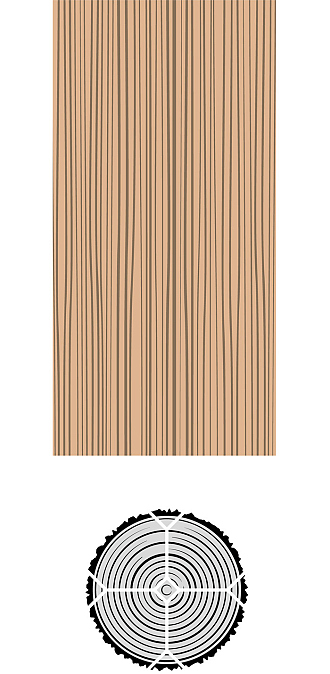

Cutting a log can be done in various ways. Each way produces a different pattern. Veneer retains the natural look and feel of real wood as well as its unique properties, showing authentic color and pattern variations. That special expression is the basis of a beautiful sheet.

Crown

Cut

Quarter

Regular Cut

Quarter

Rift Cut

Consistent Grading

Every tree is unique. By definition, we therefore never produce twice the same. And that makes our craft just as beautiful. All Iberian Fumed Eucalyptus veneer bundles are assessed in our quality center and are classified in the correct category by specialists. A quality matrix with more than 50 different sub-qualities demonstrates how accurately we do this. Because we grade very consistently and bring a sustained quality standard to the market, customers worldwide choose our products.

Precision Splicing

The selected jointing technique is the main factor in the look and feel of your project. It influences the ambiance of the project. Because this is so critical, we made it our mission to master this skill like nobody else.

Bookmatch

Bookmatch is the standard jointing method. The sliced strips of veneer are jointed mirrored, two by two. This technique clearly shows the pattern variations of the tree in the jointed sheet.

Slipmatch

Slipmatch is different because the veneer strips are matched one after the other and jointed without flipping. This is the recommended jointing technique if the veneer should be stained. As all strips have the same side up, there is no color difference between the strips.

Reverse Slipmatch

Reverse slipmatch is a variation on the regular slipmatch: the veneer is not flipped but alternately jointed head to foot. Due to this technique, the wood structure is more evenly spread throughout the veneer sheet.

Mix-Matched

Mix-Matched is literally what it says: mixing and matching. The veneer strips are jointed randomly, creating an interesting yet cohesive effect. Mix-matched is the veneer alternative for the plank effect of solid wood. It is possible to create a mix of both crown cut and quarter cut, or use crown cut only or quarter cut only. At Decospan mix-matching of veneers is taken to a special level with the use of specialized splicing machines and a team of dedicated artisans whom carefully pre-select the veneers for this process.

Years of pressing technology knowledge

We handle the most diverse types of wooden substrates in different sizes. Depending on the order, it is determined automatically with industry 4.0 technology in which of our presses the Iberian Fumed Eucalyptus veneer is brought together with the base board. What at first sight seems to be an obvious task, however, is the result of years of know-how. It’s like an iceberg: what you see physically is just a small part of a vast underlying mass of knowledge and experience. Manufacturing a high quality bespoke veneered panel is not a simple task, but a skillful art.

The main types of core material that we process are:

- MDF (including fire retardant & moisture resistant options)

- Chipboard (including fire retardant & moisture resistant options)

- Blockboard

- Plywood (including poplar, birch, WBP and fire retardant options)

Sustainable manufacturing

On average, 30% of the energy we use in our production is solar energy, generated by the solar panels we have installed at all our production sites. The remaining 70% is green energy that we source from our windmills or purchase from the energy supplier.

We use our waste wood to bring the machinery up to the right temperature. It is also how we heat our business premises in the winter months. We ensure our buildings make optimum use of natural daylight so that we do not have artificial lighting turned on unnecessarily.

Items not in stock but can be ordered, 30-45 day turnaround on orders.

Call for Details: (410) 244-0055

PANELS

We see it as our mission to produce the most beautiful and decorative oak veneered panels, enabling you to transform your most creative ideas into sensational interiors.

PANELS

Shinnoki offers prefinished wood veneered panels for architects and cabinet makers to design and create stylish and distinctive interiors.

PANELS

The Bespoke Collection has been carefully composed to inspire you and make it possible to select the most appropriate design for your project.

WALLS

With ‘Nørdus’, Decospan offers an accessible collection of veneered panels that plays into the trend towards a more Scandinavian and modernist interior design.

WALLS

Add an extra dimension to your interior with wooden wall coverings. Astrata gives your living room or office space a warm and natural look.